Try our newest merchandise

Ferrari’s first electrical automotive, the Elettrica, is the results of 4 years of inner growth, but one key part comes from outdoors Maranello.

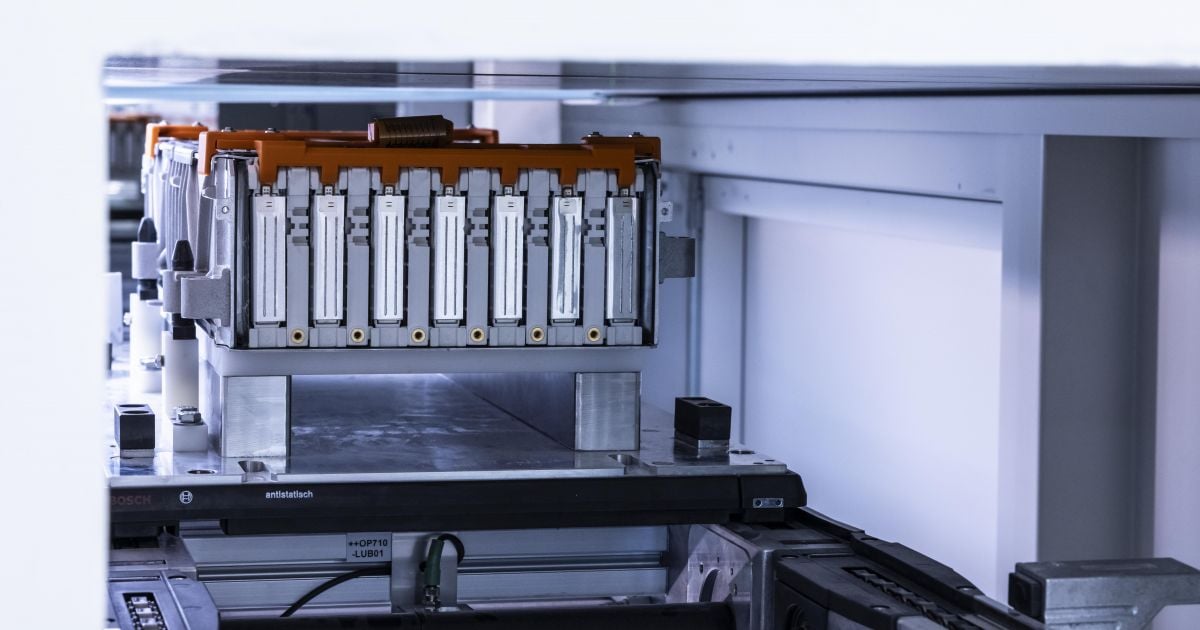

The battery cells that energy the automotive’s 122kWh structural pack are equipped by South Korean producer SK On, which signed a brand new memorandum of understanding with Ferrari in March 2024 to deepen collaboration on future cell expertise.

The MoU, signed in Seoul by Ferrari CEO Benedetto Vigna and SK On CEO Lee Seok-hee, formalises a partnership that started in 2019. Since then, SK On has equipped cells for Ferrari’s plug-in hybrid fashions together with the SF90 Stradale, SF90 Spider, 296 GTB and 296 GTS.

The brand new settlement strikes the connection past provide into joint analysis and growth, with each firms pledging to proceed to steer innovation in cell expertise.

Ferrari started work on the Elettrica in 2020 with the objective of constructing a completely electrical car (EV) that retained the precision and suggestions of its combustion and hybrid fashions. The battery took 4 years to finalise and is assembled in Maranello utilizing SK On’s nickel-manganese-cobalt (NMC) cells.

CarExpert can prevent hundreds on a brand new automotive. Click on right here to get an incredible deal.

The result’s a structural pack that acts as each an vitality supply and a load-bearing component inside the aluminium chassis. It incorporates 210 cells throughout 15 modules, every replaceable underneath Ferrari’s Perpetually program, which ensures long-term serviceability for electrified fashions.

SK On’s cells ship an vitality density of about 305Wh/kg at cell stage and 195Wh/kg at pack stage, figures in keeping with Ferrari’s official information. The battery operates at 880 volts, helps 350kW DC fast-charging and 22kW AC charging, and may ship as much as 1200 amps of peak present.

Ferrari integrates the cells into its personal casing, cooling plates and electronics inside the corporate’s new e-Constructing, the ability devoted to producing its hybrid and electrical fashions. The pack is connected at 20 factors inside the chassis, growing total rigidity and reducing the centre of gravity by roughly 80mm in contrast with an equal V8 mannequin.

The choice to associate with SK On displays each technical and strategic priorities. Whereas Ferrari continues to design and manufacture most elements in-house, large-scale cell manufacturing requires industrial capability and chemical experience.

SK On’s high-nickel NMC chemistry supplies the appropriate mixture of energy, vitality density and thermal stability for Ferrari’s efficiency and longevity targets. The provider’s versatile manufacturing scale additionally permits smaller, high-specification batches with tight high quality management.

For Ferrari, this ensures consistency and traceability throughout every batch of cells used within the Elettrica and future fashions. The MoU formalises this alignment and confirms the businesses’ intent to co-develop next-generation cell chemistry and manufacturing processes. It additionally secures Ferrari a dependable long-term supply of superior cells whereas sustaining its give attention to bespoke engineering and integration.

Contained in the e-Constructing, SK On’s cells are assembled into Ferrari’s structural casing, fitted with the model’s proprietary Battery Administration System and management electronics, and examined by simulated crash, vibration and thermal cycles. The collaboration ensures the pack meets Ferrari’s necessities for stiffness, weight distribution and sturdiness.

For SK On, the contract is small in quantity however important in visibility. Partnering with Ferrari locations the Korean battery maker in a status phase that reinforces its technological fame. For Ferrari, it supplies a confirmed vitality supply that enhances its in-house functionality in management software program, energy electronics and mechanical integration.

The partnership highlights a wider shift within the automotive panorama. Within the combustion period, Ferrari outlined itself by self-sufficiency. Within the electrical period, it’s redefining itself by collaboration with world-leading specialists.

As manufacturing of the Elettrica approaches, the alliance between Ferrari and SK On represents a mix of Italian craftsmanship and South Korean battery science, setting the path for the way Maranello will compete within the electrical age.

MORE: Discover the Ferrari showroom